a greener tomorrow

Across 36 Nations

Unmatched Service

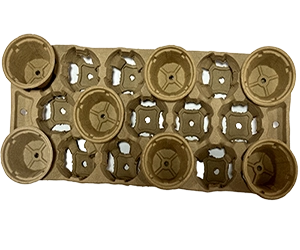

Advantages of

Moulded Pulp Packaging

The advantages of moulded pulp packaging make it a popular choice across all industries.

Sustainable solution

Since moulded pulp packaging is made from recycled paper and other natural fibers, it is biodegradable and recyclable. This helps to reduce environmental impact, making it a sustainable choice.

The production process uses less energy and water compared to plastic packaging. This reduces carbon emissions.

Cost-effective solution

Material cost is low since the primary material used is waste paper.

Light weight and durability reduce transport and replacement cost.

Customized solution

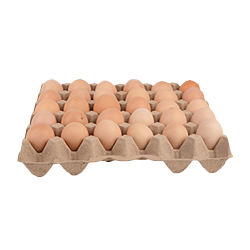

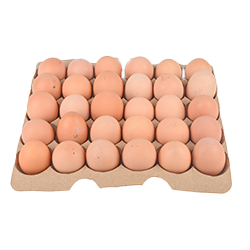

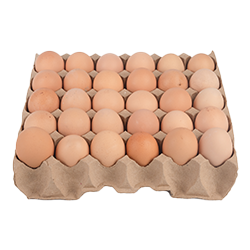

Suitable for a variety of products, such as; egg trays, fruit trays, electronic goods etc.

Flexible and can be shaped in different size, form, and strength.

Safe solution

The shock-absorbing properties make it ideal for fragile items.

Breathable material helps to maintain freshness of perishable goods such as fruits and vegetables.

Embrace sustainability

and innovation

Maspack is one of the pioneers in the world of pulp moulding packaging, making its mark over last four decades. With each passing year Maspack evolved with manufacturing state-of-the-art machinery for producing a wide range of eco-friendly moulded pulp products. These innovative machines transformed the production capacity making high-quality, sustainable packaging possible for a wide range of industries and applications. Together with the reciprocating machine and other essential components like the pulper, vacuum pump, and air compressor; Maspack brought in automation to create solutions that are future ready. So, align with Maspack’s sustainable practices and enhance your brand reputation and loyalty among eco-conscious consumers.

50 Year's of an Embarking

Journey

Maspack has a rich history of nearly 50 years. Late Mr . R V Thampan started with this initiative in the late 1970s, driven by entrepreneurial zeal. To follow his passion to create something unique and sustainable, he left his position at the Bhabha Atomic Research Centre to establish a small-scale industry in Cherthala, a small village in Southern India. When he met Mr. TJL Clarke in 1978, the concept transformed into a full-fledged joint venture with the UK, resulting in MAS UK in Derbyshire and MAS India in Cherthala.

His focus on low-cost, automated, small cylinder-type reciprocating machines helped the venture develop complete SSI units readily accessible to the developing markets. Late Mr . R V Thampan being a visionary leader empowered Maspack to adapt and develop its own machineries. This resulted in the ability to offer affordable solutions to small scale industries since the large-scale rotary machines were too costly for startups or new organizations. Today, Maspack is a global leader, converting waste paper into diverse, eco-friendly packaging solutions and serving over 36 countries worldwide.

Global presence

36 Countries

Upcoming

Events

Maspack Ltd. offers machinery with a high rate of return on investment, high quality, environmentally friendly and biodegradable packaging.